HGW65HC Slider Bearing

HGW65HC slider guide is a series of products with high assembly, high load and high rigidity, with self-aligning characteristics, able to withstand 4-direction force, even if there is a slight machining error on the mounting surface, it can still obtain smooth linear motion. Even if there is a slight machining error on the mounting surface, smooth linear motion can be obtained.

Category:

Product Center

Slider Bearing

Key words:

Product Center

Slider Bearing

PRODUCT DESCRIPTION

HGW65HC slider guide is a series of products with high assembly, high load and high rigidity, with self-aligning characteristics, able to withstand 4-direction force, even if there is a slight machining error on the mounting surface, it can still obtain smooth linear motion. Even if there is a slight machining error on the mounting surface, smooth linear motion can be obtained. This slider guide is produced by China Taiwan guide, its combined height is 30, the size of the mounting holes is 32 * 36. In the installation of the slider linear guide, care should be taken not to stamping, in order to ensure its performance and use of the smoothness of the linear guide. to ensure its performance and smoothness of use. HGW65HC slider guide is suitable for all kinds of machine tools and mechanical equipment that require high precision, high load and high rigidity movement, and it is an important choice for processing enterprises to ensure the long-term stable work of machine tools. In addition, the choice of rigid guideway is crucial to the long-term operation of the machine tool, so HGW65HC slider guideway plays a key role in the machine tool guideway system.

model | Component size [mm] |

Slider size (mm) | ||||||||||||||||

H | H1 | N | W | B | B1 | C | L1 | L | K1 | K2 | G | M | T | T1 | T2 | H2 | H3 | |

HGW 15CC | 24 | 4.3 | 16 | 47 | 38 | 4.5 | 30 | 39.4 | 61.4 | 8 | 4.85 | 5.3 | M5 | 6 | 8.9 | 6.95 | 3.95 | 3.7 |

HGW 20CC | 30 | 4.6 | 21.5 | 63 | 53 | 5 | 40 | 50.5 | 77.5 | 10.25 | 6 | 12 | M6 | 8 | 10 | 9.5 | 6 | 6 |

HGW 20HC | 65.2 | 92.2 | 17.6 | |||||||||||||||

HGW 25CC | 36 | 5.5 | 23.5 | 70 | 57 | 6.5 | 45 | 58 | 84 | 10.7 | 6 | 12 | M8 | 8 | 14 | 10 | 6 | 5 |

HGW 25HC | 78.6 | 104.6 | 21 | |||||||||||||||

HGW 30CC | 42 | 6 | 31 | 90 | 72 | 9 | 52 | 70 | 97.4 | 14.25 | 6 | 12 | M10 | 8.5 | 16 | 10 | 6.5 | 10.8 |

HGW 30HC | 93 | 120.4 | 25.75 | |||||||||||||||

HGW 35CC | 48 | 7.5 | 33 | 100 | 82 | 9 | 62 | 80 | 112.4 | 14.6 | 7 | 12 | M10 | 10.1 | 18 | 13 | 9 | 12.6 |

HGW 35HC | 105.8 | 138.2 | 27.5 | |||||||||||||||

HGW 45CC | 60 | 9.5 | 37.5 | 120 | 100 | 10 | 80 | 97 | 139.4 | 13 | 10 | 12.9 | M12 | 15.1 | 22 | 15 | 8.5 | 20.5 |

HGW 45HC | 128.8 | 171.2 | 28.9 | |||||||||||||||

HGW 55CC | 70 | 13 | 43.5 | 140 | 116 | 12 | 95 | 117.7 | 166.7 | 17.35 | 11 | 12.9 | M14 | 17.5 | 26.5 | 17 | 12 | 29 |

HGW 55HC | 155.8 | 204.8 | 36.4 | |||||||||||||||

HGW 65CC | 90 | 15 | 53.5 | 170 | 142 | 14 | 110 | 144.2 | 200.2 | 23.1 | 14 | 12.9 | M16 | 25 | 37.5 | 23 | 15 | 15 |

HGW 65HC | 203.6 | 259.6 | 52.8 | |||||||||||||||

|

|

|

|

|

|

1.Preload accuracy Hiwin genuine products: There are various pre-pressure options, such as Za, Zb, Zq, etc.; There are various precision options, such as P, C, H |

2.Raw materials Hiwin genuine products: Made of steel imported from Germany and Japan, the screw rods are cast: the steel balls are uniformly imported from abroad; |

3. Heat treatment Shangyin genuine products: many years of experience, advanced equipment, mature, scientific and complex heat treatment technology |

4. High strength steel | 5. High speed and quiet operation |

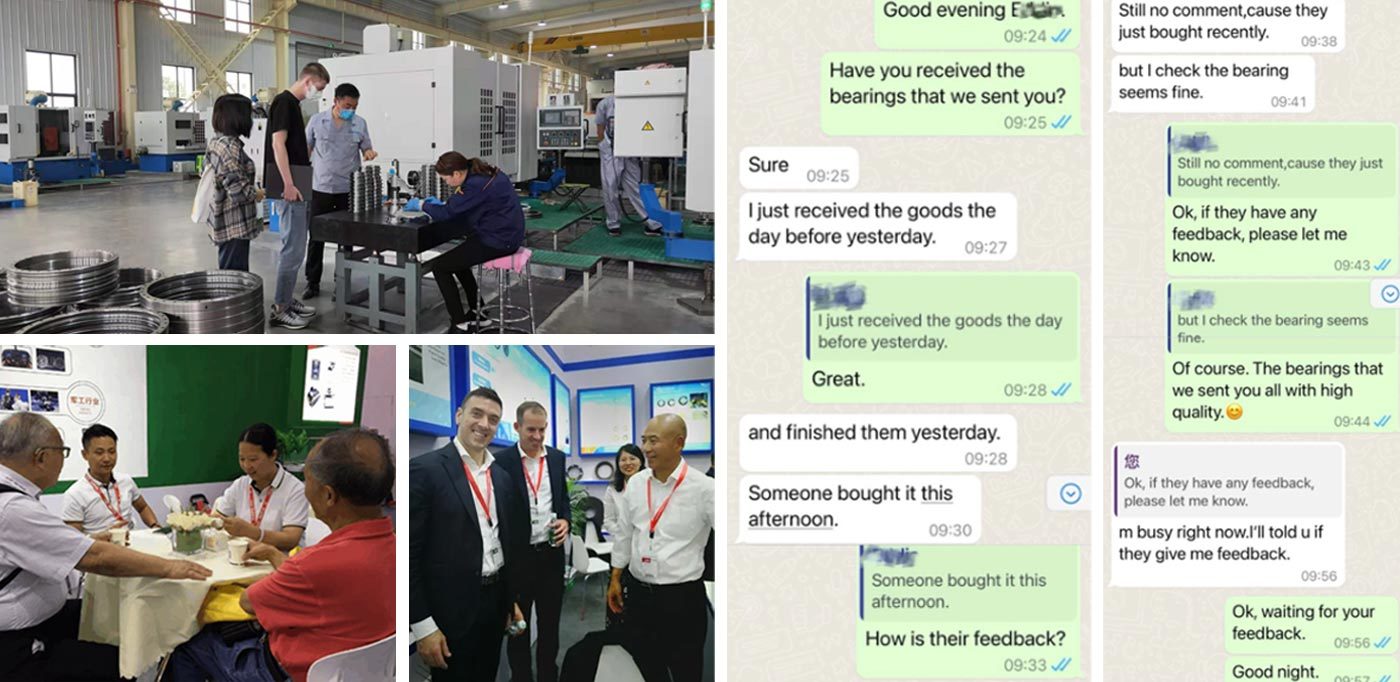

FACTORY APPEARANCE

We have a professional sales team dedicated to providing first-class service to our customers. Our products cover a variety of different types of bearings, including rolling bearings, sliding bearings, etc. We cooperate with many internationally renowned brands to ensure product quality and reliability.

PACKING AND SHIPPING

Our team is always ready to assist with any enquiry or order and in addition to our extensive expertise and knowledgeable team we offer a wide range of first class products and services. Our inventory includes a wide variety of bearings and we are committed to assisting you in finding the ideal solution for your individual requirements.

APPLICATION AREAS

Our team is committed to providing first-class service and products to meet all of your bearing needs. Please feel free to contact us for more details or to explore how we can help you with your specific bearing needs. We appreciate the opportunity to work with you and look forward to building a lasting partnership.

CUSTOMER VISIT

FAQ

Q: How do you make our business relationship good in the long run?

Q: Are you a trading company or a manufacturer?

Q: Can I visit your factory?

Q: Can we take some samples? Any fees?

Q: Can I have a sample for quality test?

Q: Are you a producer or a commercial company?